Welcome to Anytester (Hefei) Co., Ltd!

Welcome to Anytester (Hefei) Co., Ltd!

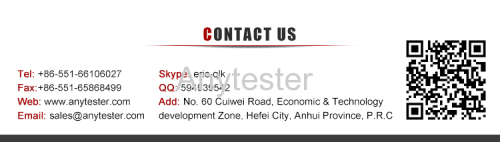

Mobile: 188 5510 5986

E-mail: sales@anytester.com

Address: Building 3#, Jixian Road, Economic-Technological Development Area Hefei, Anhui, China (Mainland)

You are here:

Feature

1.It is suitable for puffing, refining, bleaching and dyeing cotton, wool, artificial wool, acrylic and blended yarn. It also can be used for pre-treatment and after- treatment.

2.This Special Machine is designed to be low energy,low lift and larger quantity flowing.When working under high temperature,It could keep it's characteristic.

3.It's three in one that concludes new model.It has low LR,which save materials and reduce the cost by way of improving its structure.

Main parts

1.Machine Main tank and equipment

2.Steam Heat exchanger

3.Spay pipe

4.Dosing tank and equipment

5.Transmission part

6.Water pump

7.Electric control

Standard and features

1.The main tank is made of imported stainless steel 316L with high quality.

2.Nozzle is with corrosion-resistant stainless steel 316L.

3.Stainless steel mixed flow pump of high performance.

4.The dosing tank equipped with mixing heating.water feeding,flowing back and dyes feeding.

5.Reliable PLC program controller.

6.Automatic water level indicator.

7.There're several safety operating system in the machine.

8.It's convenient for yarn loading,yarn unloading and cleaning.

Technical parameters:

1.Design pressure:0.44Mpa

2. Maximum working pressure:0.4Mpa

3.Design temperature :140℃2

4.Maximum working temperature :135℃

5.Heating rate:20℃~130℃about 35 minutes(Saturated vapor pressure:0.7Mpa)

6.Cooling rate:130℃~80℃ about 25 minutes(Cooling water pressure:0.3Mpa)Cooling water temperature:5℃~10℃

7.Liquid ratio:1:6 ~10

Parameter Detail

Model | KS-4-1500 |

Kier Type | Horizontal Kier |

Dye Type | Steam pressure |

Kier diameter | 1600mm |

Total no. of arm | 4 |

Arm Length | 1500mm |

Capacity | 50 KG-60KG |

*The machine is equipped with: | |

Vertical main body | 316L |

Arms | 304 |

Heat-exchanger | 304 |

Circulation pump-quanrun | 304 |

Dyestuff tank | 304 |

Circulation pump electric motor | 7.5 KW |

Voltage | 380V/50HZ |

Configuration

Parts | Configuration | |

Brand | Country of origin | |

Dyeing Controller | AS9000A(Touch Screen) | China |

PLC | LS(LG Group) | Korea |

Motor | Wannan | China |

Stainlees Steel | SS316/SS304 | China |

Inverter | V&T | China |

Solenoid Valve | JELPC | Japan |

Main Pump | Quanrun | China |

Switches | Schneider | France |

Contactor | Schneider | France |

Relay | Schneider | France |

Main Tank Water Level Sensor | Windsurfer level gauge | Chian |

Butterfly Valve | Botukie | China/Germany Joint Venture |

Motor | Botukie | China/Germany Joint Venture |

Voltage | 380V/50HZ | |

Specification

Model | No. Of Arms | Arm Length (mm) | Capacity (KG) | General Power (KW) | Dimension (L*W*H)(mm) |

KS-4-1500 | 4 | 1500 | 50-60 | 7.5 | 2340*3800*1870 |

About us: