Welcome to Anytester (Hefei) Co., Ltd!

Welcome to Anytester (Hefei) Co., Ltd!

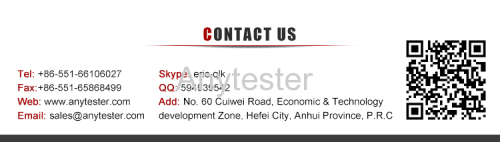

Mobile: 188 5510 5986

E-mail: sales@anytester.com

Address: Building 3#, Jixian Road, Economic-Technological Development Area Hefei, Anhui, China (Mainland)

You are here:

Introduction:

AT101 Series Universal Testing Machine addresses the needs of standardized and routine testing, providing the user high quality at the most affordable price. The single column testing systems are suited for tension and/or compression applications where tests are less than 5 KN and lab space is limited. They are typically used for quality control and production testing.

Application:

AT101 Series Universal Testing Machine is suitable for tensile, compression, bending, shearing, peeling, tearing and other mechanics performance tests of metals, building components, large fasteners, composites, wood products, plastics, rubber, textile, geosynthetics, non-metallic and composite materials. It completely conforms to GB, ISO, ASTM, JIS, DIN and other test standards.

Features:

★ Imported robust linear motion guide increases lateral stiffness and ensure linear crosshead travel. This results in accurate crosshead alignment thus reducing variability in measurement data and producing better overall accuracy

★ Non-clutched drives, rated for full speed at maximum force

★ Compact design saves lab space

★ Imported servo motor with precise planet-gear speed reducer provides higher driving efficiency, low noise and free of maintenance. No need replace lubricates which has longer working life

High Quality at affordable price

1) Pre-loaded ball screws and heavy duty bearings assure long life with zero backlash as well as linear low force and through zero performance. The result is accurate and repeatable measurements that truly represent the specimen characteristics rather than load frame deficiencies

2) Fully-protected lead screw covers provide longer life and greater operator protection

3) Easy-to-clean aluminum column covers with chamfered corners to facilitate access to the test area. T-slots are built in for simple, convenient attachment and positioning of testing accessories

4) Photoelectrical encoder built in servo motor system is for position measurement of crosshead

5) Built-in bidirectional load cell is assembled in the middle

6) crosshead to prevent any collisions and simple to perform compression or tension tests

7) Dual action over-travel limits on all frames provide the highest level of safety and meet all international standards

8) crosshead to prevent any collisions and simple to perform compression or tension tests

9) Dual action over-travel limits on all frames provide the highest level of safety and meet all international standards

10) High-speed, low vibration, world-class, maintenance-free, imported AC servo motor and servo controller

11) Remote control keypad facilitates test operation

12) Full one-year warranty on parts and labor

13) Free software upgrading

Full complement of test accessories

Extensive range of accessories to meet test requirements in almost any application or industry: plastics, metals, biomedical, composites, elastomers, components, automotive, aerospace, textiles, and more.

1) Tension grip

2) Peel/tear fixture

3) Compression fixture

4) Flexure fixture

5) Film COF test fixture

6) Exchangeable load cells: 10N~2kN

7) Long travel extensometer

8) Clip-on extensometer

Machine Dimensions:

Frame type | W*D*H A*B*C (mm) | Crosshead Travel H(mm) | Front Opening Space L(mm) | Adapter (mm) | Pin (mm) |

Standard | 490*530*1590 | 1000 | 100 | Ф20 | Ф10 |

Specifications:

Model | AT101A | AT101B | AT101C | AT101D | AT101E | AT101F | AT101G |

Capacity | 50N | 100N | 200N | 500N | 1kN | 2kN | 5kN |

Type | Single column | ||||||

Calibration standard | ISO 7500, Class 1 / Class 0.5 | ||||||

Force range | 0.2% ~ 100%FS / 0.4 ~ 100%FS | ||||||

Force accuracy | ±1.0% / ±0.5% of reading | ||||||

Force resolution | 1/500000FS | ||||||

Position accuracy | 0.50% of reading | ||||||

Position resolution | 0.042μm | ||||||

Crosshead speed | 0.01 ~ 750mm/min | ||||||

Crosshead speed accuracy | ±1.0% / ±0.5% of set speed | ||||||

Crosshead travel(without grip) | 1000mm | ||||||

Dimension | 530*490*1590mm | ||||||

Power requirements | AC 1Phase, 110/220V±10%, 50/60Hz | ||||||

Weight | 90Kg | ||||||

Standard configuration:

No. | Item | Quantity |

1. | Main machine | 1 set |

2. | Sensor | 1 pc |

3. | Software | 1 copy |

4. | Clamp | 1 pair |

5. | Remote control panel | 1 pc |

6. | PC | 1 set |

7. | Printer | 1 set |

8. | Communication wire | 1 pc |

9. | Power cord | 1 pc |

10. | User Manual | 1 copy |

11. | Packing list | 1 copy |

12. | Qualify certificate | 1 copy |

Optional accessories

No. | Item | Quantity |

1. | Sensor (50N, 100N, 200N, 500N, 1kN, 2 kN, 5kN) | |

2. | Clamp for different purpose | |

3. | Extensimeter |

Shipping information:

Model | AT101 |

Package | Fumigated wooden case |

Crated dimension (W*D*H) | 700*700*1850mm |

Crated weight | 130Kg |

Lead time | 30 working days |

About us: