Welcome to Anytester (Hefei) Co., Ltd!

Welcome to Anytester (Hefei) Co., Ltd!

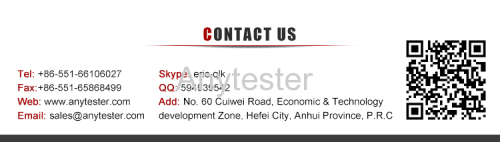

Mobile: 188 5510 5986

E-mail: sales@anytester.com

Address: Building 3#, Jixian Road, Economic-Technological Development Area Hefei, Anhui, China (Mainland)

You are here:

Application:

AT227 Pilot Scale Melt Spinning Machine is a main key equipment in synthetic fibre production. This machine uses high temperature ceramic to heat and melt the polymer sample, and extrude the sample to be liquid trickle from a spinneret under the effect of inert gas pressure, then nascent fibers form under the effect of air cooling. It is specially designed for small batch production test to simulate the field production.

Features:

★ Material Melting and Spinning Part

It consists of extruding part, extrusion measuring head, metering pump, spinning system and cross air-blowing device.

1. Extruding Part

l Extruding screw made of high-temperature alloy tool steal with three sections of electric heating, heating power up to 3KW.

l It adopts heating rods to heat and copper bush for heat soaking.

l Independent temperature controlling and adjusting module for each heating section and adjustable temperature range of from room temperature up to 320℃.

l Programmable temperature controller for each section with PID control and auto-turning to keep the temperature accuracy with ±0.5℃.

l Driven by frequency-variable motor with power of 2.2KW.

l Water-cooling copper coiler at the discharge port to rapid adjust the temperature of the discharge port.

2. Extrusion Measuring Head

l Independent pressure sensor and temperature sensor mounted on the extrusion measuring head, real-time monitor the pressure and temperature.

l Pressure sensor accurate to 0.1N and temperature sensor accurate to ±0.5℃.

3. Metering Pump

l All of main body of pump, gears and bearings are made of tool steel, high temperature resistant up to 400℃.

l Heating power up to 3KW.

l Applicable liquids of viscosity ≤ 40000Pas and temperature ≤400℃.

l Pump cleaning temperature not more than 450℃.

l Input pressure up to 12Mpa.

l Maximum pressure difference up to 25Mpa.

l Standard flow of 2.4cc/rev.

l Driven by frequency-variable gear motor with power of 320W.

l Real-time acquisition and display of melt pressure and temperature.

l Built-in pressure sensor and temperature sensor in pump.

4. Spinning System

l Crystal fiber heating furnace with heating power up to 3KW;

l Adjustable temperature range from room temperature to 320℃.

l Maximum material filling up to 3L per time.

l Three heating sections, rapid heating, high heat efficiency and excellent heat insulation.

l Barrel made of 316 stainless steel, thickened wall and uniform material heating.

l Barrel adopts full copper bush for heat soaring and uniform heating.

l Solid relay to control heating elements, accurate temperature controlling, durable and no noise.

5. Cross Air-blowing Device

l Water-cooling fan to blow.

l Cool air passes through the halftone of air filter to enter the channel.

l Effective blowing area of 150×150mm.

★ Oiling & Winding Part

1. Rotary Oiling Device

l PA6 roll with adjustable opening and closing design, convenient to start and stop at any time.

l Oiler driven by gear motor with power of 450W with variable speed of 300~1000m/min.

l Oil tank made of 304 stainless steel, rust-proof and durable.

2. Hot Rolls

l Diameter of 125mm and length of 125mm.

l With polishing and chroming surface treatment, hard surface and excellent wear resistance.

l Electric induction heating, clean, environment-friendly and low maintenance cost.

l Temperature range from 70℃ to 200℃.

l Independent variable frequency motor with power of 450W to drive for independent speed adjustment.

l Speed range of 100~500m/min.

3. Winding Head

l Rubber friction pulley.

l Speed range from 300m/min to 1000m/min.

l Maximum winding pole size of 120×¢320mm.

★ Measuring and Controlling Part

1. Data Monitor

l Real-time monitoring of material temperature and wall temperature.

l Air paths adopts full 304 stainless steel pipes, valves and pressure meter.

l Programmable temperature controller, PID automatic temperature control and programmable temperature controlling for three heating sections.

l PC remote control and interface display of extruding speed, hot roll speed, winding speed, metering pump speed, temperature and other necessary alarm and signal.

2. Over-limit Alarm

l Over load alarm.

When over load, system will shut off the electricity.

l Over temperature alarm.

When over temperature, machine stops heating.

l Extruding pressure over-limit alarm

When extruding pressure beyond the limit, motor stops rotating.

l Metering pump rotation speed alarm

When metering pump rotation speed is away from the set value, auto alarm display.

Technical Specification:

Model | AT227 |

Melt spinning device | |

Heating power of extruding screw | 3KW |

Extruding screw diameter | ¢25mm |

Temperature range | RT~320℃ |

Temperature accuracy | ±0.5℃ |

Pressure sensor accuracy | 0.1N |

Melt pump max. temperature | 400℃ |

Flow of melt pump | 2.4cc/rev |

Spinneret plate | 24 holes, hole dia.: 0.1mm Outer diameter: 90mm Material: 316L stainless steel |

Max. Power of crystal fiber furnace | 3kw |

Max. Heating temperature of furnace | 320℃ |

Cross air blow device | 150×150mm |

Winding system | |

Speed range of oiling roll | 300~1000m/min |

Hot roll temperature range | 70~200℃ |

Hot roll diameter | 125mm |

Hot roll length | 125mm |

Winding head speed range | 300~1000m/min |

Max.winding diameter | 320mm |

Drive system | |

Drive motor of melt pump | 320W |

Drive motor of extruding screw | 2.2KW |

Drive motor of hot roller | 450W |

Drive motor of oiling system | 450W |

Temperature control | |

Temperature control accuracy | ±0.5℃ |

Melt pressure sensor accuracy | 0.1N |

Material of gas line | 304 stainless steel |

Power supply | AC220V, 50Hz |

Standard Configuration:

No. | Item | Quantity |

1. | Main machine | 1set |

2. | Spinneret plate | 1pc |

3. | Packing list | 1pc |

4. | Quality certificate | 1pc |

5. | User manual | 1pc |

About us: